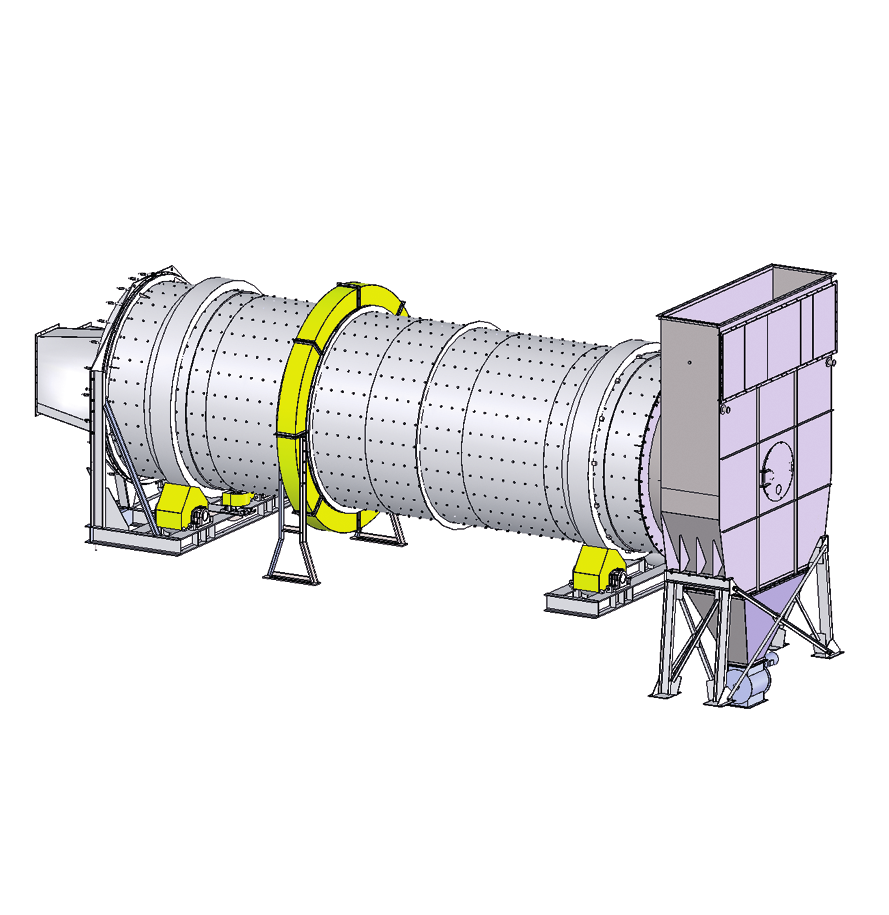

Sugar dryer-cooler

Drum-type, horizontal sugar dryers, of the DE (Dunford-Elliott) type, are the most widespread in the practice of the sugar industry. The designed drum provides optimum conditions for effective drying and cooling of sugar crystals fed from sugar centrifuges. DE drum dryers ideally combine mechanical treatment of the crystal surface with low speed drying and cooling of the sugar. To increase the drying and cooling effect on the sugar, the hot and cold air streams are separated by installing a central tube in the drum. Thanks to this design, the drum dryer achieves an excellent ratio between energy consumption and water evaporation.

Advantages of DE type drum dryers:

- The drum of the dryer runs on rollers in a horizontal arrangement (no need to tilt the drum in the direction of the discharge).

- The flow of sugar in the direction of the chute is ensured by a conical arrangement of tangential shutters.

- All components and surfaces in direct contact with the sugar are made of chromium-nickel steel.

- The use of inverter drives ensures proper start-up and smooth regulation of the drum’s operating parameters, as well as optimal consumption of the installed power.

- Uniformity of sugar heating, drying and cooling.

- High efficiency (drying and cooling is much faster than in other types of installations).

- Reliability and stability of operation and low electricity consumption.

It should also be emphasised that drying and cooling equipment designed as sugar dryers (both inlets supplied with hot air) can achieve significantly higher outputs, provided that the drying station is supplemented with the installation of a separate – additional – sugar cooler. In addition, we also offer equipment for the sugar drying and cooling station, both on the sugar transport line and the supply/extraction installation of the plant.