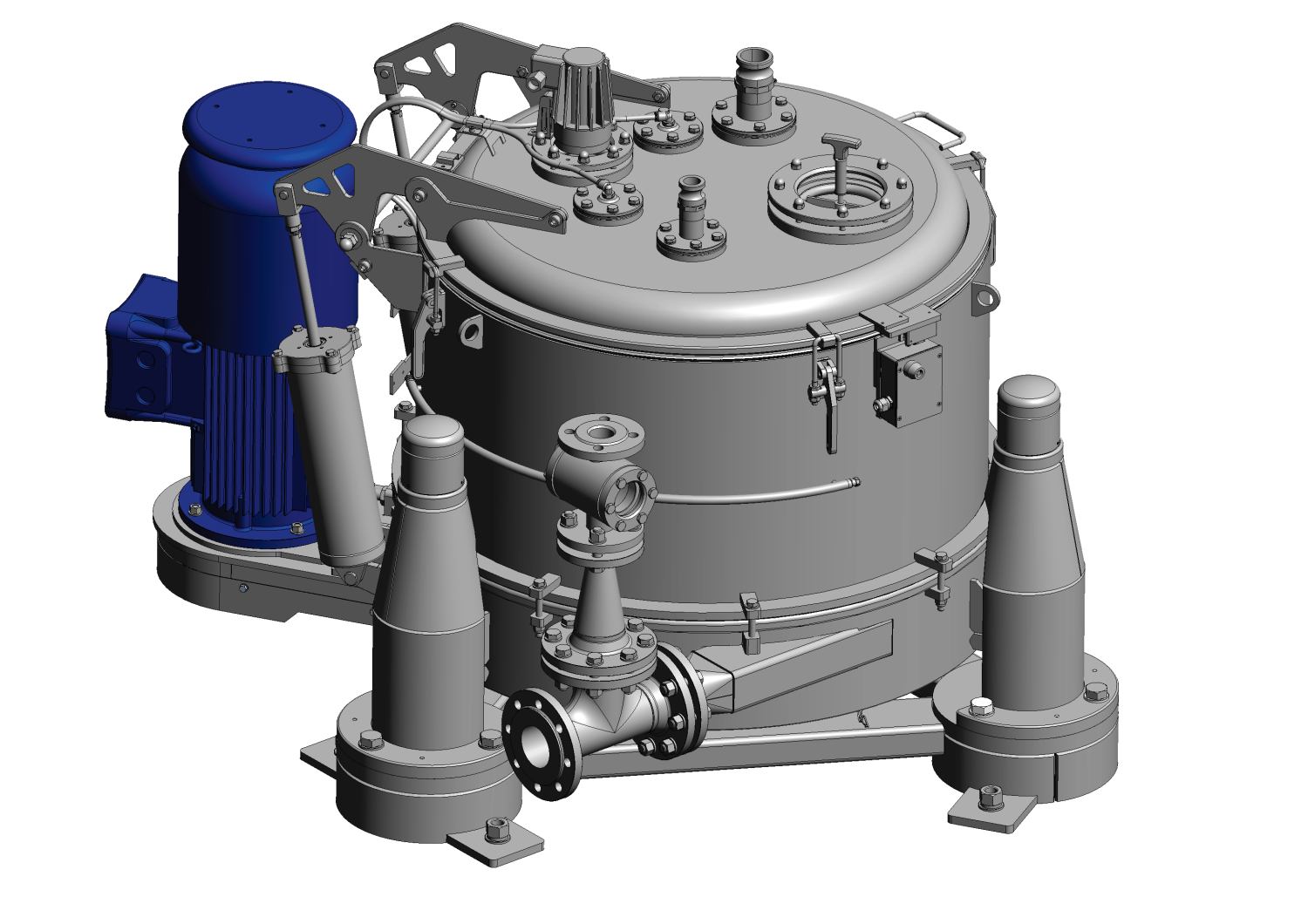

Three-column centrifuges

Three-column filter centrifuges are designed for separating mixtures of liquid and solid in crystalline, granular or fibrous form, and for dewatering various materials with low liquid phase content. Centrifuges of this type are widely used for the dewatering of fine-grained suspensions in the chemical and pharmaceutical industries.

A centrifuge is a machine in which the separation of solids from liquids takes place on a filtration screen. They have a perforated drum on which a metal mesh and/or fabric is applied to form the filter barrier. The solid particles subjected to centrifugal force settle on the inner semi-permeable surface of the centrifuge drum, forming a so-called filter cake, and the liquid (leachate) with the remains of solid fine particles passes through the filtration screen and is then released into the area between the housing and the drum, from where it is discharged to the outside.

The drum, housing, cover and elements in direct contact with the centrifuged medium are made of stainless steel, while the drive components and base plate are made of carbon steel protected by anti-corrosion coatings. The centrifuge is operated via a control panel. For safety reasons, the operation of the lid opening is secured with mechanical safety switch.

On request, the centrifuge is provided with an explosion-proof motor. WT-800EEx centrifuge – is intended for operation in pharmaceutical and chemical industries in explosion hazard zones. It can be additionally equipped with an inertization system, which feeds gaseous nitrogen from an external installation to the inside of the centrifuge and to the bearings in order to displace oxygen and eliminate the possibility of explosive mixtures during work with hazardous substances.

The inner surface of the drum can be coated with a chemically resistant, FDA-certified material. During normal operation, the noise level does not exceed 70 dB (A). Under extreme start-up conditions, the noise level may be higher.

The main filtration materials used are:

- Cotton fabric, resistant to 9% H2SO4 5% NaOH,

- Rayon fabric resistant to 15 – 25 % HCl,

- Plastic fabric.