Mixture preparation system

The correct preparation of the mixture of lime stone and coke/anthracite is essential for the lime calcination process to run smoothly. Feeding the lime kiln with a mixture that is free of impurities, too fine particles and in the right proportions ensures that the right calcination temperature is reached and the required lime parameters are obtained. We offer complete preparation systems for the lime kiln. Our scope of supply includes the design, manufacture and installation of the equipment including automation and control.

Pre-feed hopper

The pre-bunker is a small vessel for storing batches of raw material loaded by wheeled transport equipment. Its size is selected according to the customer’s needs. A vibrating conveyor is installed in the lower part of the hopper, which starts up in an automatic cycle and empties the feed material onto the conveyor. The hopper and its support structure are made of steel. The inside of the hopper can be lined to absorb the noise generated during loading and unloading.

Limestone drum sifter

Due to the frequent problem of purity of the raw material for the production of quicklime, pre-screening is used in front of the limestone bunkers. Drum sifting is a commonly used solution with proven performance. The device has two functions. Firstly, it pre-screens the undersized stone fraction. In addition, it reduces the content of sand and other impurities that would enter with the transported stone into the bunkers of the feed material and then into the lime kiln, causing negative effects on the calcination process. The screen is fed directly from the feed conveyor or via a distributor if there is more than one raw material. The rotating sifter drum moves the feed material towards the discharge. At the same time, the smaller fractions pass through the screen slots and are separated and placed on transport equipment or directly on the screenings dump. The screened raw material exits through the discharge and is transported to the conveyors.

Belt conveyors

Every mixture preparation system is equipped with conveyors. They have the function of transporting both raw material, products and waste material generated in the batch preparation process. We offer belt conveyors for transporting limestone, coke or anthracite as well as quicklime. Depending on your needs, the conveyors can be equipped with weather protection covers. We offer single-acting and double-acting conveyors. The dimensions are selected according to the expected capacity and the nature of the work. If required for the removal of debris from the belt, we provide and install scrapers. Each conveyor is fitted with the necessary sensors to provide information on the operating status of the device. We supply the conveyors with the necessary guards as well as safety systems. We offer the possibility to design and manufacture support structures together with service platforms.

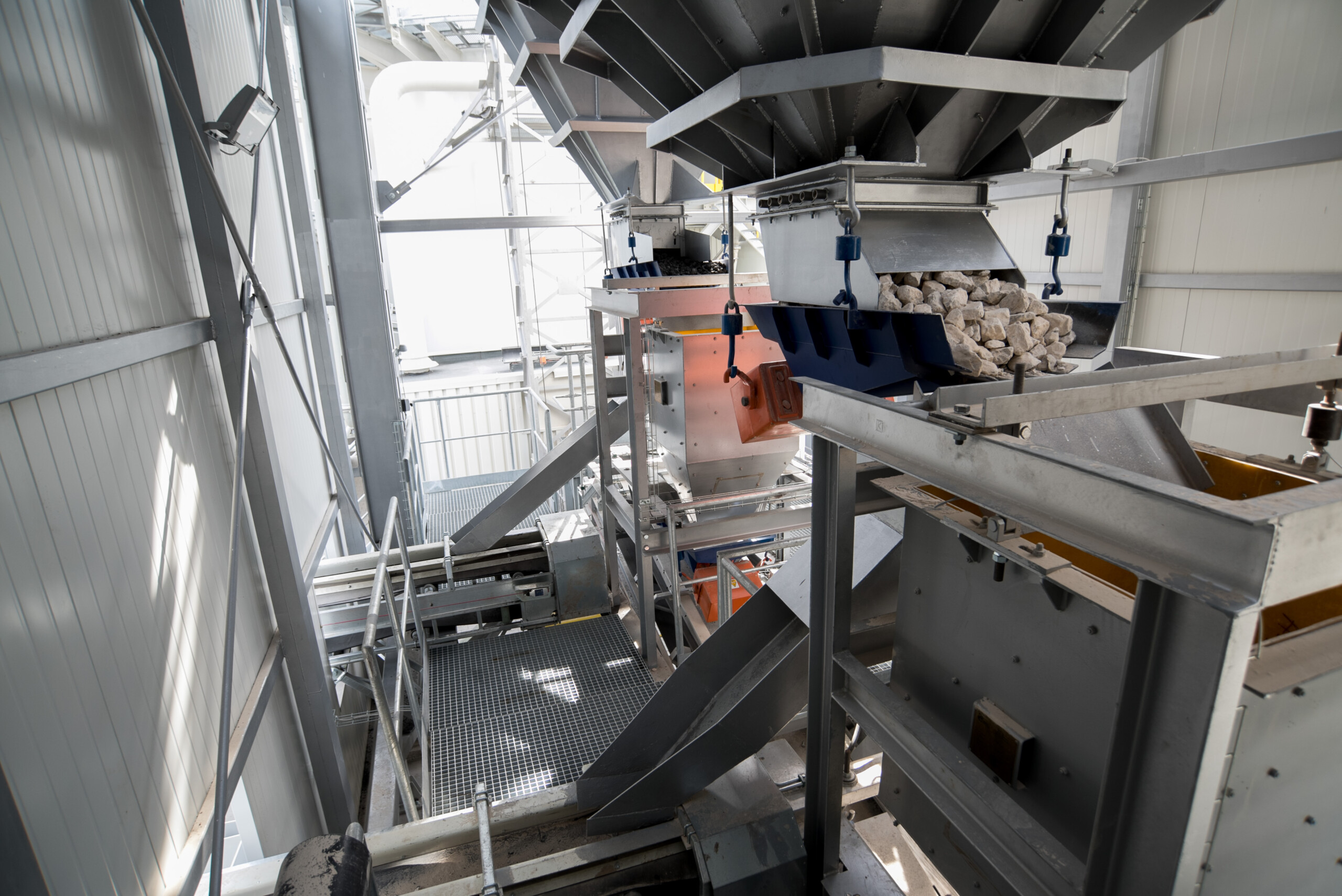

Flexowell conveyor

The Flexowell conveyor is a compact solution for transporting raw materials to significant heights while reducing the space required for its installation. It is an interesting alternative to scraper conveyors due to its method of loading and unloading material. It consists of a horizontal bottom station into which the transported raw material is loaded. A drum with a tensioning mechanism is installed in this station. The lower station is connected to the vertical shaft. The upper station is located at the top of the conveyor. A drive drum connected to the drive and a hopper discharge are installed in the upper station. The conveying element for the raw material is a Flexowell type rubber belt equipped with transverse sills and lateral corrugations. The belt’s transverse sills prevent the material from spilling over on a transport section with a steep incline. The lateral corrugations prevent the material from spilling out sideways and enable the belt to scroll smoothly over the directional drums. In the upper part of the conveyor, we install a service platform for the operation and maintenance of the upper station. Due to the size of the unit, the conveyor is delivered to the site in components for final assembly. The device is equipped with a set of sensors monitoring its operation.

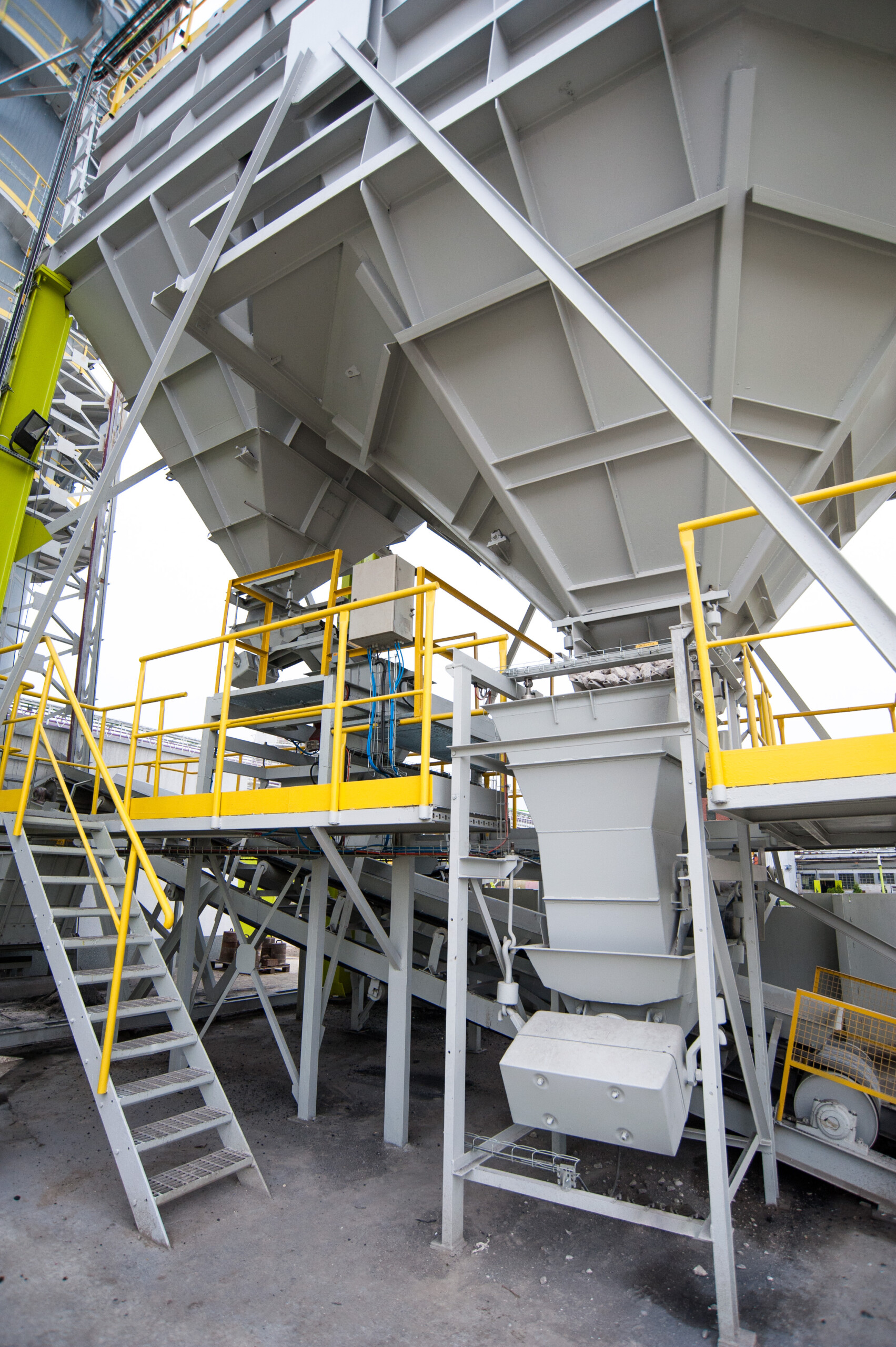

Limestone and coke/anthracite storage system

We offer an integrated storage system for lime stone and coke or anthracite. Our tanks are made from the appropriate quality steel to guarantee safe long-term operation. The capacity of the tanks is adapted to the size of the lime kiln and other parameters such as the planned loading frequency. The construction of the tanks is supported on four steel legs of a length which makes it possible to place a system for the preparation of the kiln mix under the tank. At the customer’s request, we use solutions to reduce noise emissions. The tanks can be completely encased in noise-absorbing panels or lined with a specially adapted lining. As a standard feature of the storage system, we offer service platforms allowing access to the upper part, where the devices for filling the bunkers are installed. Each storage tank is equipped with a level sensor which indicates the filling level of each tank.

Mixture weighing system

The mixture stored in the lime stone and coke/anthracite storage tanks must be properly prepared before being fed into the lime kiln. This is done using our mix preparation system, which is a set of equipment that performs individual tasks. The removal of the raw materials from underneath the bunkers is carried out by means of vibrating metering units. The batching units are additionally equipped with a sifting grate. Its task is to finally sift out the smaller fraction of the raw material that arises in the absence of pre-screening, in transport or in the bunker itself due to the movement of the charge and interaction. The sifted fraction is transferred to belt conveyors and further to the refuse dump, while the sifted product is transferred to weighing hoppers. Their function is to prepare a suitable portion of limestone and coke/anthracite. The weighing hoppers are equipped with weighing systems that can be calibrated according to customer requirements. The emptying of the weighing hoppers onto a conveyor transporting the mix to the skip is carried out using vibrating feeders. Each of these has adjustable capacity. The mix preparation system is equipped with sensors to enable automatic operation and to obtain information about possible failures. At the customer’s request, we integrate the system into the existing infrastructure, including the control and visualisation algorithm.